M Dialysis AB (or µ-Dialysis) develops and markets leading clinical micro dialysis solutions for advanced clinical research and general intensive care usage. Svekon is an engineering company that helps clients bring ideas from vision to a finished product. The two companies started working with PiezoMotor in 2016

Applications

M Dialysis success story

Solving the problem of the pulsating flow in a syringe pump

A new micro dialysis machine

M Dialysis had their existing micro dialysis machine, which the CEO referred to as a “petrol-driven computer”. They wanted to create an improved new version, “turning it into an Apple computer”. Because the existing model was bulky, the CEO wanted to create a smaller version. The new model would feature instant and continuous monitoring of the patient’s health status by measuring the changes of chemical substances in the body. The technique is revolutionary as it can measure an almost indefinite number of substances in real time, indicating chemical changes in the body even before any symptoms have presented themselves. This allows the intensive care doctors to diagnose critical changes in the patient’s chances of not only survival, but potentially also a much better recovery and quality of life after stabilization. M Dialysis assigned the engineering company Svekon (Svensk Konstruktionstjänst) to lead the product development process. The Svekon team was led by senior consultant Niklas Svahn.

The challenge of designing a compact and non-pulsating pump with high resolution

One key issue stopped M Dialysis from finalizing the pump development. As their technology could measure an indefinite choice of chemical substances almost immediately (no longer any need to run lab tests and get results hours later), they needed a pump or similar that offered a reliable and constant slow flow of the liquid

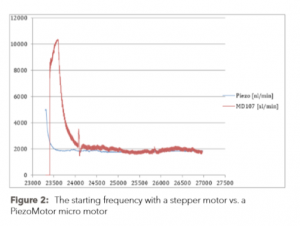

passing through the patient’s body to collect samples. “The application relies on an extremely low flow rate of down to 0.1 µl/min. With a stepper motor, this means one step every minute, which creates a pulsating flow. By using PiezoMotor’s micro motor, we were able to obtain a steady continuous flow”, concludes Svahn.

“All traditional stepper motor-driven pumps had too low resolution, causing the liquid to pulsate through the sensor”, recalls Olof Nord, the CEO of M Dialysis. “The problem was that we had to calculate an average from several measurements instead of having reliable single test results. This was of course much less powerful and harder to explain to our users, doctors, who base lifeor-death decisions on this data. To enable the real leap in innovation that we wanted, we needed a different solution”, concludes Nord.

PiezoMotor made the slow non-pulsating flow possible

After several failed attempts to find an optimal solution with traditional technology, Svekon’s innovative product designer Carl Öjerstam recalled a meeting with PiezoMotor and how impressed he was with the possibilities their micro motors offered. Excited about potentially finding a solution, Svekon’s Niklas Svahn contacted PiezoMotor to set up a meeting. PiezoMotor’s field application engineer Per Bendixen brought a starter kit and showed both Svekon’s technical consultants and the M Dialysis team how PiezoMotor’s micro motor worked.

It took only a few minutes and everyone could conclude that the problem of finding a non-pulsating flow was solved. “We knew immediately that this was our solution”, recalls Olof Nord. “The piezo technology was brilliant and the PiezoMotor team was competent and service-minded.

It is inspiring to see that groundbreaking innovation like this comes from a Swedish company”, Nord concludes. “We are very excited about PiezoMotor’s micro motor technology—we have never seen anything similar before”, reflects Niklas Svahn. “Although it was a new technology to us, the PiezoMotor team offered great support that made it quick and easy for us to get started.” Together, M Dialysis, Svekon, and PiezoMotor worked out how to create the ideal solution, so that a standard PiezoMotor micro motor model could be used. “The PiezoMotor micro motors quickly proved to offer high resolution and precision at surprisingly competitive prices. We are happy to use PiezoMotor products again—also with other clients in the future. We can see that PiezoMotor’s micro motors would be useful to all clients needing highprecision motors with controlled motion”, finishes Svahn.

“To M Dialysis, this technology was essential and made it possible for our revolutionary product to reach its full potential”, concludes Olof Nord. He continues: “We look forward to involving PiezoMotor in our future product development projects, from the beginning this time. Their expertise proved to be of great support in our product development, leading to both better and more economical solutions.”

“It is always our ambition to create the best technical solutions for our clients—but also at the best possible prices. If you use our standard motors, the price for the high resolution and precision that you get is really competitive. This is almost always possible if our clients involve our development engineers early on in the product development process”, concludes Johan Westermark, the CEO of PiezoMotor.